Loop Library Member

The general library member information is displayed at the top of the screen. To build a loop, select components from the Plant Component Selection Bar to add to the plant diagram. The properties section displays all of the loop fields. It can be viewed by clicking on the bottom properties bar.

Plant Component Selection Bar

The selection displays categories of components that can be added to a loop. These categories are:

Each loop type will display the categories and components that are valid. Click on the category button to expand it and view the components that can be added to the loop. Select a component on the bar by clicking on it. The plant diagram will highlight the valid locations for placing the component on the loop. To drop a component on the plant diagram, click on one of the green dot locations. Below is a description of each category:

Pumps

The Pumps category in the Component Selection Bar displays the valid pump types that can be added to the loop. The available pumps for all loop types are shown below. For more information on each type of equipment see the Equipment Library.

● Constant Volume Pump Not-Headered

● Variable Volume Pump Not-Headered

● Constant Volume Pump Headered

● Variable Volume Pump Headered

Pumps that have been added to a loop will be displayed in the Properties Section under Components. Each component displays information from the equipment library member that has been selected. The library member may be changed but its information is not editable. The fields displayed for pumps are:

● Name

● Full Load Energy

● Pump Head

● Motor Efficiency

● Motor Heat to Fluid

● Flow Control

Equipment

The Equipment category in the Component Selection Bar displays the valid component types that can be added to each loop type. The available equipment per Loop Type is shown below. For more information on each type of equipment see the Equipment Library.

|

1 Chilled Water Loop

A Air Cooled Chiller

B Water Cooled Chiller

A Absorption Chiller

B Engine Driven Air Cooled Chiller

C Engine Driven Water Cooled Chiller

D District Cooling

E Temperature Source

2 Hot Water Loop

A Boiler

B Water Heater

C District Heating

D Temperature Source

3 Condenser Loop

A Cooling Tower

B Fluid Cooler

C Evaporative Fluid Cooler

D Well

4 Mixed Water Loop

A Boiler

B Water Heater

C District Heating

D Temperature Source

E Cooling Tower

F Fluid Cooler

G Evaporative Fluid Cooler

H District Cooling

I Ground Heat Exchanger

J HX w/ Controls

5 Heat Exchanger Loop

A Chilled Water Loop to Chilled Water HX

a Air Cooled Chiller

b Water Cooled Chiller

c Absorption Chiller

d Engine Driven Air Cooled Chiller

e Engine Driven Water Cooled Chiller

f District Cooling

g Temperature Source

B Chilled Water Loop to Mixed Water HX

a Air Cooled Chiller

b Water Cooled Chiller

c Absorption Chiller

d Engine Driven Air Cooled Chiller

e Engine Driven Water Cooled Chiller

f District Cooling

g Temperature Source

C Hot Water Loop to Mixed Water HX

a Boiler

b Water Heater

c District Heating

d Temperature Source

D Hot Water Loop to Hot Water HX

a Boiler

b Water Heater

c District Heating

d Temperature Source

E Condenser Water Loop to Condenser Water HX

a Air Cooled Chiller

b Water Cooled Chiller

c Absorption Chiller

d Engine Driven Air Cooled Chiller

e Engine Driven Water Cooled Chiller

f District Cooling

g Temperature Source

F Condenser Water Loop to Chilled Water HX

a Cooling Tower

b Fluid Cooler

c Evaporative Fluid Cooler

d Well

G Condenser Water Loop to Mixed Water HX

a Cooling Tower

b Fluid Cooler

c Evaporative Fluid Cooler

d Well

H Mixed Water Loop to Hot Water HX

a Boiler

b Water Heater

c District Heating

d Temperature Source

e Cooling Tower

f Fluid Cooler

g Evaporative Fluid Cooler

h Ground Heat Exchanger

I Mixed Water Loop to Chilled Water HX

a Boiler

b Water Heater

c District Heating

d Temperature Source

e Cooling Tower

f Fluid Cooler

g Evaporative Fluid Cooler

h District Cooling

i Ground Heat Exchanger

6 VRF Loop

A VRF Outdoor Unit

B Water VRF Outdoor Unit

|

Thermal Storage

The Thermal Storage category in the Plant Component Selection Bar is only available in the Chilled Water Loop type. The two available components are Ice Storage and Chilled Water Thermal Storage. For more information on each type of see the Equipment Library.

Heat Exchanger

The Heat Exchanger category in the Component Selection Bar displays the valid component types that can be added to each loop type. The available equipment per Loop Type is shown below. For more information on each type of equipment see the Equipment Library.

|

1 Chilled Water Loop

A HX w/controls

B HX Waterside Economizer

2 Hot Water Loop

A HX w/controls

3 Condenser Loop

A HX w/controls

4 Mixed Water Loop

A HX w/controls

5 Heat Exchanger Loop

A Chilled Water Loop to Chilled Water HX

a HX w/controls

b HX Waterside Economizer

B Chilled Water Loop to Mixed Water HX

a HX w/controls

C Hot Water Loop to Mixed Water HX

a HX w/controls

D Hot Water Loop to Hot Water HX

a HX w/controls

E Condenser Water Loop to Condenser Water HX

a HX w/controls

b HX Waterside Economizer

F Condenser Water Loop to Chilled Water HX

a HX w/controls

G Condenser Water Loop to Mixed Water HX

a HX w/controls

H Mixed Water Loop to Hot Water HX

a HX w/controls

I Mixed Water Loop to Chilled Water HX

a HX w/controls

|

Controls and Sensors

For Loops, the only available control is a Water Temperature Set point Controller. This controller can be connected to components added to the loop to sense the water temperature in that node. The control strategy can then be defined in the Properties section of the Controls tab.

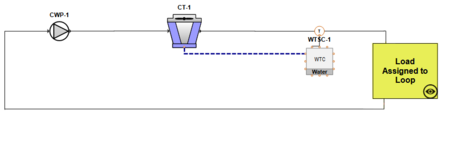

Plant diagram

The plant diagram is a graphic representation of a loop. It displays the supply side components as well as a demand box. As components are selected in the component selection bar, the plant diagram will highlight valid locations for placing them with green dots. To drop a component on the plant diagram, click on one of the green dot locations. To delete a component from the plant diagram, click to select the component and hit delete. As components are added to the plant diagram, they will be added to the components tab of the properties section.

Each loop type in the Loop Library has business rules that will help create a valid loop configuration. When you are finished configuring your plant, click the validation button to display Validation Messages that will help you fix invalid configurations or missing data.

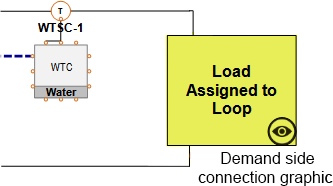

Demand Side or Demand Box

The plant demand side contains equipment that places a load on the primary equipment. This might include coils, baseboards, radiant systems, etc.

Within the demand section, if you are using the Plant Wizard or are located in the Assign Loops section, you can view supply side components that the demand is connected to. An example would be a condenser loop that is connected to one or multiple chillers.

These assignments or connections can be viewed by clicking on the component or loop that it is connected to.

Supply Side

Supply side will contain primary equipment such as chillers or boilers on the supply side loop. Each supply side must be connected to a demand side and vice versa. You can select components by using the plant component selection bar. Each component has rules associated to them on where they can be placed within the diagram. Each valid location will have a green dot for placement. If the component location breaks a rule, then the validation rules will appear and will give a suggestion on what to fix in the particular loop.